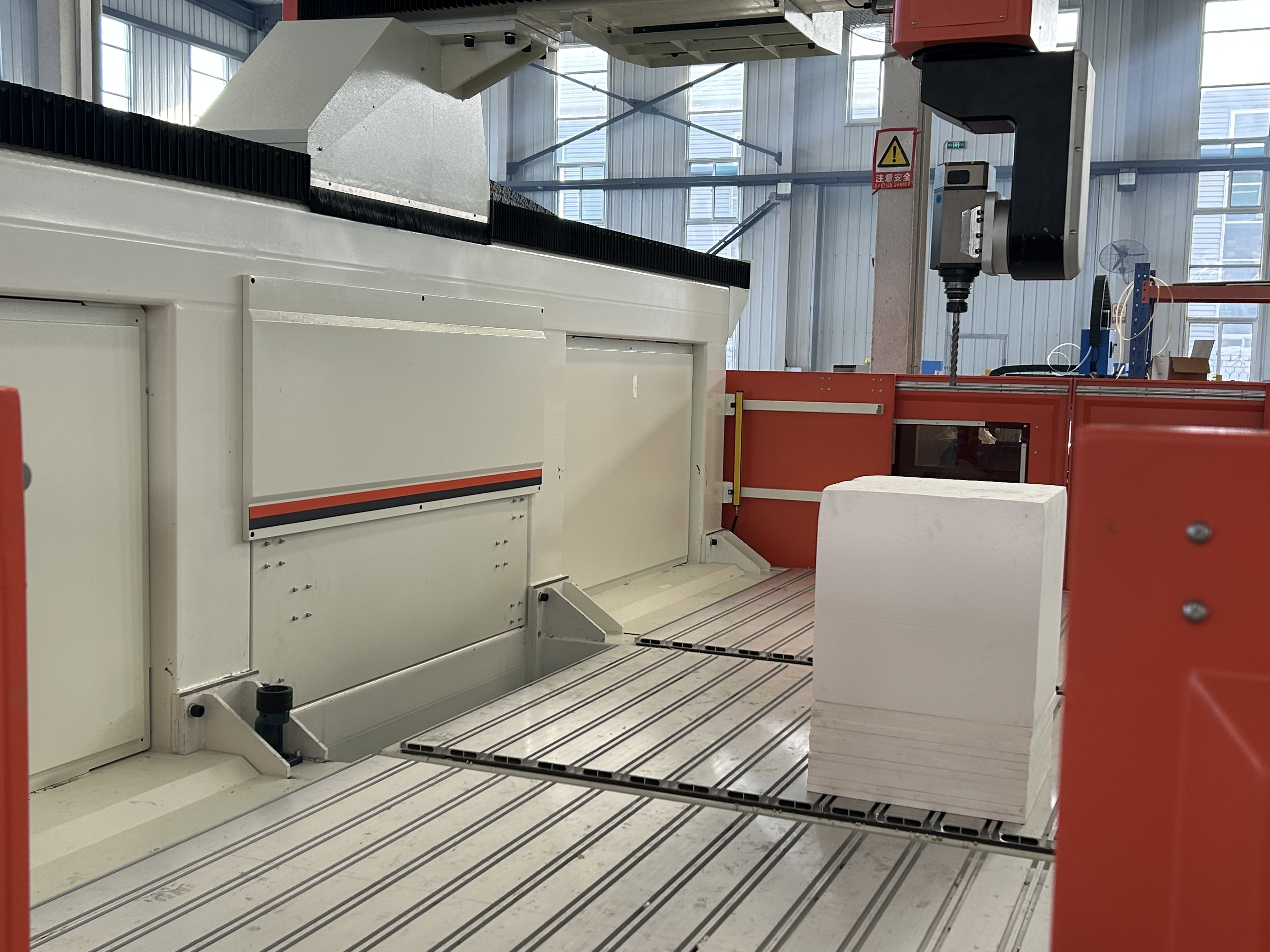

| No | Items | Name | Location | Parameters | |

| 1 | Spindle configurations | Spindle |

HQD |

brand:HQD power:12Kw Spindle rotating :24000rpm Cooling:water cooling Tool Holder:HSK63F ER32 |

|

| Double rotating | The heavy-duty five-axis swing head uses Taiwan's high-rigidity reducer, which has high braking torque and rigidity and high precision. | ||||

| Tool Magazine | 6-position tool change magazine; the maximum tool specification (length/diameter) allowed is 200mm/100mm. If the adjacent workstations are not equipped with tools, the maximum tool diameter allowed is 300mm. | ||||

| 2 | Servo | Syntec | taiwan | X/Y1/Y2/Z/B/C axes all use Taiwan's new generation high-speed Servo motors (maintenance-free),bus control, good transmission efficiency,high transmission accuracy, and no need to return to the origin during movement; the Z-axis servo motor has a brake. | |

| 3 | Inverter | Delta | Taiwan | Taiwan Delta's Ms300 series inverter is impact-resistant and has good stability, providing a guarantee for the spindle speed adjustment. | |

| 4 | Controller | Syntec | Taiwan |

The fully digital Taiwan Xinda five-axis control main system, the WINCE system developed by Magic CNC, has RTCP automatic tool tip following function and tool length and diameter compensation function, supports keyboard and mouse; can import and execute programs through U disk, Internet transmission and other modes. System bus control, with power-off memory function, origin memory, no need to return to the origin when starting up. |

|

| Taiwan's new generation of five-axis system special machine adjustment movable wireless handwheel can adjust the speed of the handwheel control operation by 1-100 times, and can perform X/Y/Z/4(B)/5(C) multi-axis selection control on the handle, which is convenient and simple, easy to operate, and improves work efficiency. | |||||

| 5 | Automatic oil lubrication | Software control, automatic timing and quantitative lubrication, and lubrication of moving parts as needed. | |||

| 6 | Rails | HIWIN | Taiwan | The XYZ axis uses Taiwan-made TWIN high-precision guide rail sliders, which adopt the best precision design. All four sides have high rigidity and ultra-heavy load capacity, low noise, smooth movement, and a Gothic four-point contact design. It can withstand loads in all directions and has strong rigidity and high precision. | |

| 7 | Ball Screw | HIWIN/ TBI | Taiwan | The Z axis uses a ball screw to drive the ram through a coupling to control the lifting. The ball screw is produced continuously using the world's highest level of mechanical equipment made in Japan, and has high rigidity and high precision. | |

| 8 | Racking and pinion | T-WIN | Taiwan | The X/Y1/Y2 axis uses Taiwan-made M2 high-temperature quenched helical racks, which have the characteristics of smooth travel, large transmission torque, low noise and high speed. | |

| 9 | Electrical Devices | Schneider | France | To ensure the durability and safety of key electrical components, relays, circuit breakers and push button switches are all from French Schneider. | |